Red Rose Reproductions Latta Inlay Tools

Red Rose Reproductions were approached by Lie-Nielsen in 2023 asking whether they would be interested in taking over their line of inlay tools. These tools are designed specifically for stringing inlay, a popular decorative technique in Federal pieces, along with certain regional furniture, particularly southeast Pennsylvania, from the 18th century. Educator/cabinetmaker Steve Latta, the original inspiration of these tools, offered input and encouragement as they worked to bring them back to the market. Stringing inlay is when veneer of a different species, usually holly, is cut and sized into thin strips and let into grooves cut into the work. Various patterns and designs can be created, and even lettering.

The process of doing stringing inlay starts with veneer, either shop cut or commercial. The veneer is first cut into strips, called stringing, that are a bit wider than the groove will be deep, usually around 1/8'' (3.2mm). Next, these strips are passed through a thicknessing gauge to get them to a precise thickness to fit into the grooves in the work.

Grooves are cut into the work using either the radius gauge, for grooves on a radius, or the straight-line cutter for grooves parallel to the edges of the work. Once the grooves are cut and the stringing is prepared, the stringing is glued into the grooves with yellow glue. After the glue is set, excess stringing is trimmed flush with the work.

There are four tools offered by Red Rose Reproductions as described below:

- Slicing gauge. This tool is used to slice veneer into thin strips to form pieces of stringing. It works much like a marking gauge, and can, in fact, be used for that purpose just as well. This is the only tool that is not ambidextrous, so it is available in both right-hand and left-hand versions to suit the user’s preference.

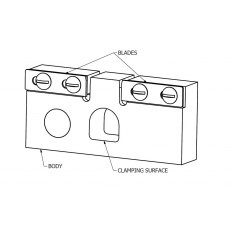

- Thicknessing gauge. Used to trim stringing to a precise thickness to fit into the grooves made by the radius cutter and straight-line cutter. This tool has two cutters, and one can be set up to get the stringing close to size, and the other for the final sizing.

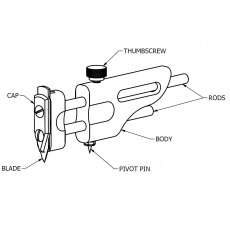

- Radius cutter. Used to cut grooves to receive stringing on a radius. It can cut a radius from 11/16'' (17mm) to 4'' (100mm). With the optional extension rods, it can cut any size radius required. Each pair increases the maximum radius that can be cut by 3'' (76mm). Comes with two pivot points of different heights.

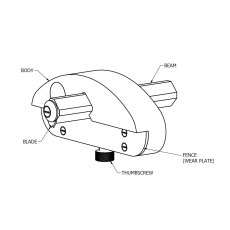

- Straight-line cuter. Used to cut straight grooves parallel to the sides of the workpiece. Comes with two cutters: one for cross grain and one for with the grain cutting.

The standard cutters for the radius gauge and the straight-line cutter are .031'' (0.79mm) thick. They plan to offer other thicknesses in the near future, allowing for different widths of stringing to be used. Cutters on all tools are made of 1095 spring steel, hardened to Rc 52. All are sharpened, but the thicknessing gauge should have a burr turned on the cutters for best performance.

The radius cutter body is black anodizes aluminum, and the other wood tools are made of hard maple with an oil finish. Other components are brass stainless steel, and steel.

Working with Steve Latta, they plan to offer more information about these tools in the form of videos.

Also, we recommend streming the video by Steve Latta, “Fundamentals of Inlay; Stringing, Line & Berry”. Available at Lie-Nielsen Toolworks.