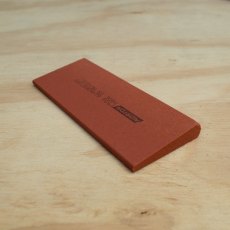

Man-made Oilstones

Norton long lasting Oil Stones are economical and have been the standard of craftsmen for over 75 years. Oil stones will sharpen and hone a fine edge on any tool, but have limitations for polishing. Oil stones require a light mineral oil (make sure it is food friendly if you are sharpening your kitchen knives) to suspend metal and abrasive particles away from the stone’s cutting surface which keeps the stone free-cutting. Like water stones, oil stones required periodic flattening.

The clever stuff - India sharpening stones are manufactured using a proprietary process that impregnates them with a petroleum based product that allows the lubrication used during the sharpening process to stay on the stone’s surface. As a result, the metal from the object being sharpened and small pieces of abrasive that break off the stone become suspended in the lubricant. This prevents these materials from imbedding into the sharpening stone’s surface, keeping it free cutting and making it easy to keep its surface clean.

With use, oilstones develop a concave wear pattern. To re-flatten, attach 120 grit waterproof sandpaper to a glass plate, wet, then 'sand' the stone until flat or use a flattening plate.

.png)